Engine Mountings, Engine Removal & Replacement & General Guide To Reassembly

Introduction

What follows is only some information on performance modifications to the Aurelia. Given its active contemporary competition activity, there were a large number of factory modifications. Information on these is limited in detail although references to them are available. The Nardi 'kits' are well known and were available on new cars. Some information is given below on these.

Much activity however has been devoted in recent years to making Aurelias competitive in historic motor competition but unfortunately this information is not yet recorded (perhaps for obvious reasons) and is not available in this manual.

Nardi Performance Modifications

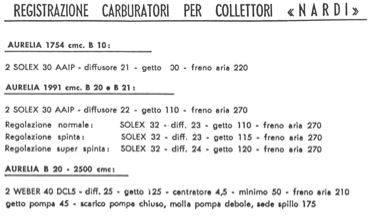

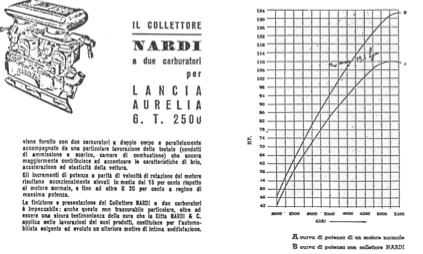

The first item below is from a photocopy of an original Nardi brochure for the Aurelia together with a letter to an owner in Holland in 1960

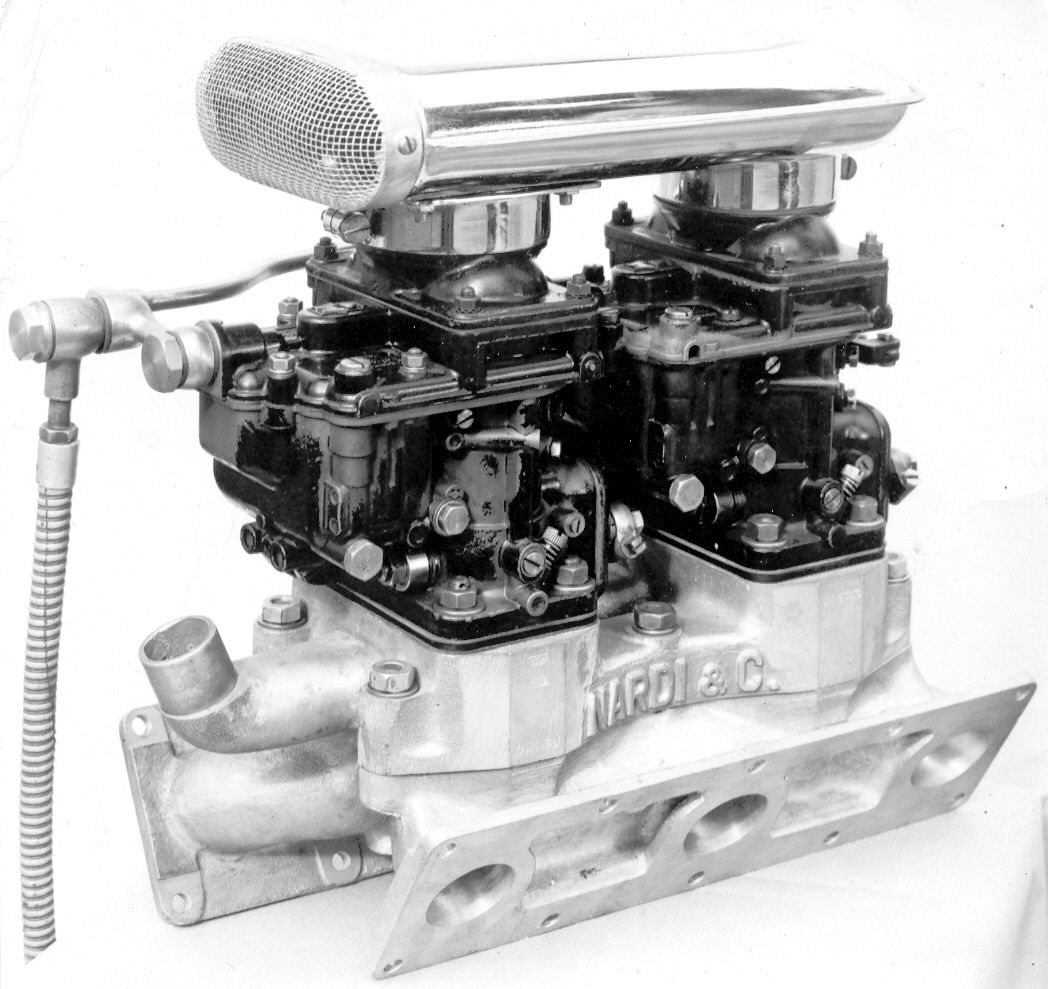

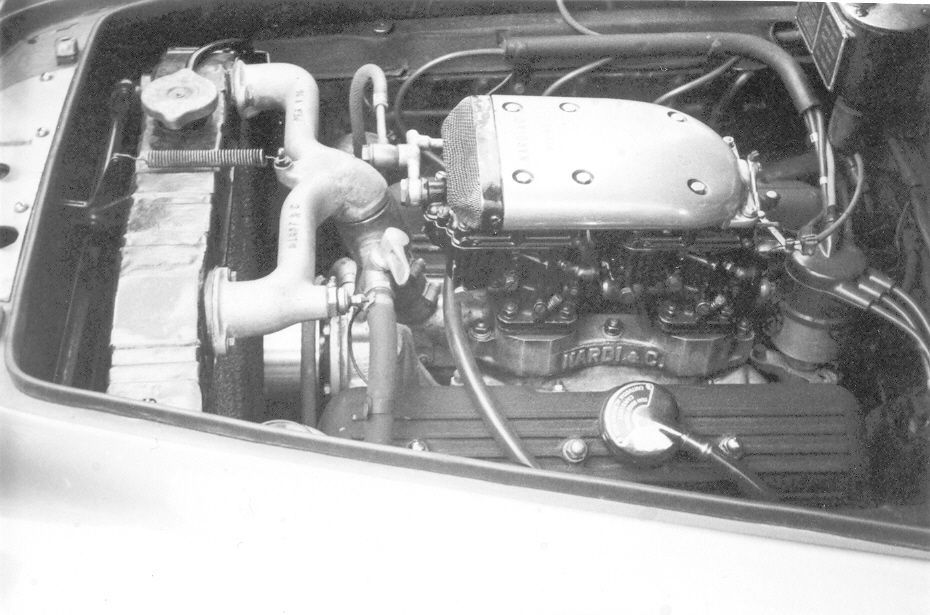

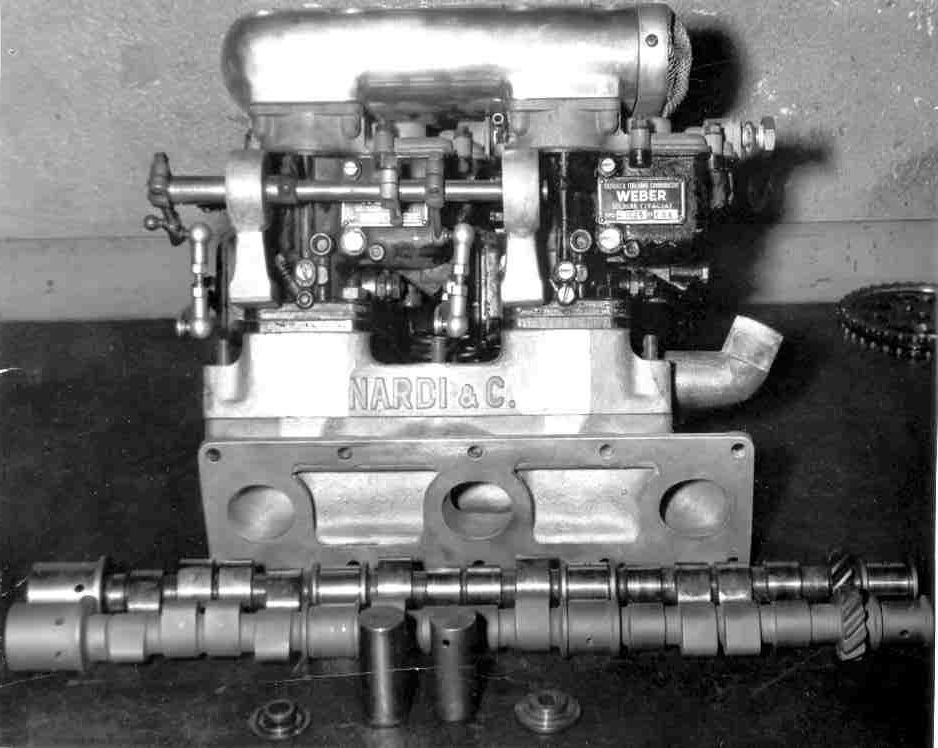

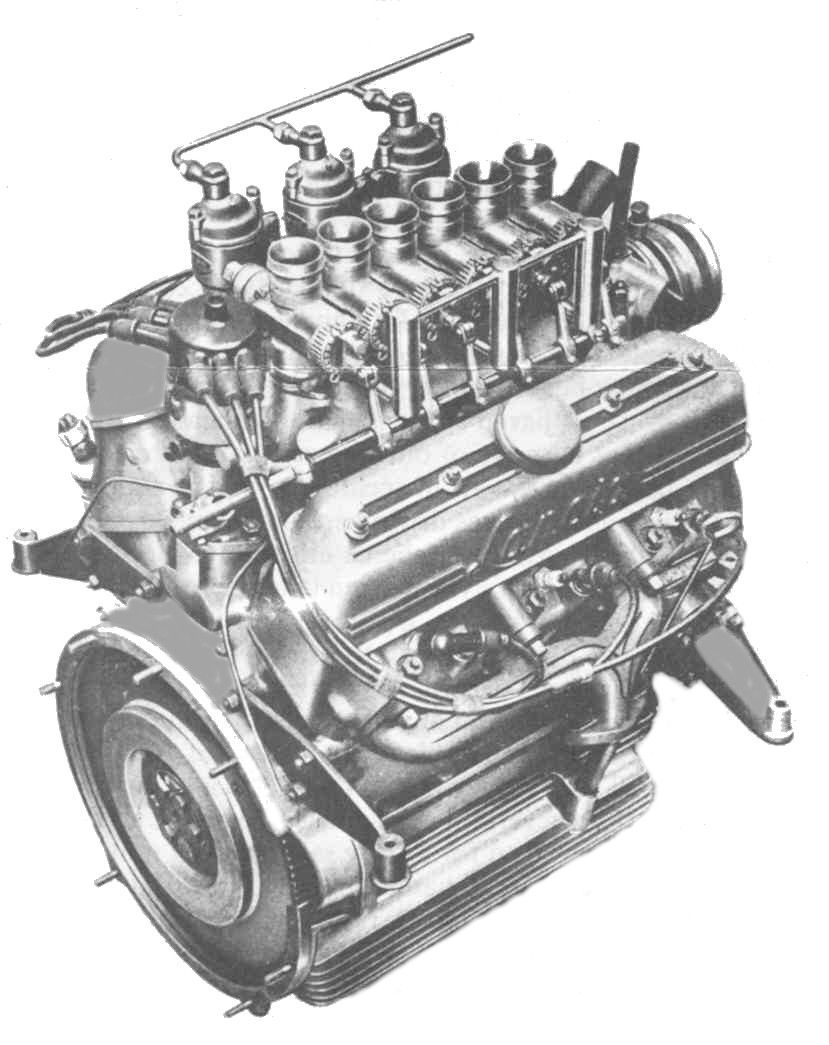

The photographs, which follow, show Nardi induction modifications such as the dual intake manifold with ball bearing linkage. The dull grey camshaft in foreground is the Nardi item reground after Everlube processing. The other camshaft is a well-worn stock item. Valve retainer on left is standard and that on the right is a special alloy retainer for use with Pratt & Witney valve springs. Valve lifter on left is a Lancia part in steel with 4 holes whereas that on the right is a cast iron part with one large hole in the shank.

Tim Burrett's (1989) view of Nardi's claim for power output (130-145 BHP) from his two-carburettor manifold is that they were exaggerated. On its own he feels more than normal horsepower would be a surprise. The camshaft is however probably worth 20 hp. The use of stronger valve springs should be avoided as the increased load on the camshaft followers causes wear and pitting - a problem in any case. Modern cam profiles result in lower valve accelerations even if giving more period and lift and therefore do not need more spring pressure.

Others say that the twin carburettor Nardi set-up used now with modern fuel, experiences less fuel starvation than can be the case with the standard single 2-choke Weber.

To: Mr J de Kruyff, Holland. From: Torino September 10, 1960

Dear Mr de Kruyff, I beg your pardon for having delayed in answering your letter but I was travelling on business. I assure you that by our special manifold & camshaft & by the cylinder heads 1.5 mm lowered, the power of your Aurelia engine must exceed 145 BHP.

By a clearance of 1.2 mm the correct timing will be: intake 15º / 47º - exhaust 36º / 25º.

By an intake clearance of 0.25 & an exhaust clearance of 0.35, the right timing will be about the following: intake 37º / 80º - exhaust 60º / 47º.

Concerning the carburettor regulation please follow the instructions listed in the enclose sheet.

Nardi Set-up with Two Weber Carburettors for the B20 GT2500 Aurelia

Carburettors on Nardi Manifold with Special Air Cleaner

Same Set-up fitted onto Engine

Nardi Performance Kit for the B20 GT2500 Aurelia

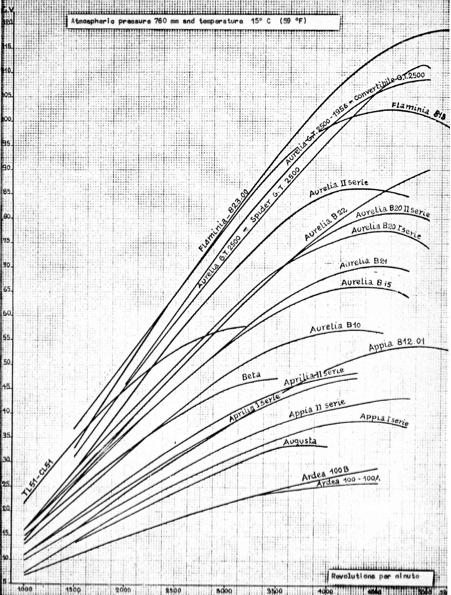

01.11.3 - Lancia C. AST Sketch 143 I (22/1/1969): Power Curves on Engine Test Bench

The weight P (kg) on the engine brake arm corresponding to a certain engine power CV at n engine revolutions per minute is calculated by the formula: P = CV / 0.001 n. 0.001 is the fixed coefficient for brake arm 716 mm long.

‘Aurelia Performance Modifications’ by Mark L Dees (California)

Lanciana, American Lancia Club previously published in UK Lancia Motor Club Journal, September 1958

Retyped & slightly edited by Paul Mayo August 2007

Cylinder Heads

Cylinder heads can be milled 1 mm for an 8.7 compression ratio or 1.5 mm for an 8.9 ratio. Nardi supplied special thin head gaskets to accomplish the same result. When the heads are off it is a good idea to match the ports in the heads with the passages of the intake & exhaust manifolds. When replacing the heads be very careful to clean the threads of the head studs & nuts, & never use more than 29 lb.ft. or 39.3 N.m. of torque when tightening the nuts. The studs are quite weak, snap easily if the nuts are wound up too tight, & are quite hard to remove & replace unless the head is taken off.

Valve Gear & Camshaft

Nardi characterises the valve gear as the weak point of the Aurelia engine, & certainly I have had enough trouble in this department. The first point is to discard the steel valve lifters with which certain Aurelia engines are equipped & replace them with standard Lancia cast iron lifters. The steel lifters, which have four small holes on the wearing surface, tend to wear & gall the camshaft lobes to an extreme degree. The cast iron lifters, which have one large hole in the side of the lifter next to the wearing surface, are slightly heavier but much more compatible with the wearing surfaces.

Camshaft galling can also be caused by valve spring float caused by inadequate spring tension. Of course, valve spring tension can be too great, but the springs in my engine were so weak, either by nature or fatigue, that tension with the valves open was only 80 ft. lbs. A local camshaft expert suggested this could be doubled & some Pratt & Whitney aero engine valve springs were used with modifications to the retainers & keepers to give a seat tension of 81 lbs. & an open tension of 190 lbs. For those who hesitate to go to such lengths, Nardi recommended the use of 1 mm spaces under the standard valve springs.

Nardi did not recommend the use of the Lancia sodium-filled exhaust valves in a modified engine. In my engine modified MG TD valves were used.

To obtain long life in the Nardi reground camshaft, it was subjected to the “Everlube” process in which iron & manganese phosphates with an outer coating of molybdenum disulphide are bonded to the camshaft surface by furnace heating. The phosphates are porous & retain oil like a sponge, & the molybdenum acts as a dry lubricant during the first minutes of engine operation that are so critical in the life of a camshaft. The “Parco Lubrite” & “Dry-Lube” processes are similar to this. Good results are also obtained from the “Superweld” process in which a non-ferrous alloy of nickel, chrome & boron is hot-sprayed onto the lobes, fused in a furnace, & then finish ground to the proper profile.

A certain amount of cam wear can be eliminated by never allowing the engine to idle below 900 rpm, as it seems that the interaction of lifter & lobe is more destructive at low rpm than at high, & by avoiding the use of multi-viscosity oils, which tend to be deficient in film strength.

As for the Nardi cam, I am happy enough with it, but Nardi developed a new profile, which he claims will add an extra 18 to 20 HP. Recommended clearances for the Nardi cam are 0.30 mm for intake & 0.40 mm for exhaust. These will be a little noisy, but according to Nardi will reduce the possibility of burnt valves.

Cylinder Block

Never lift the engine using the hexagonal bolt heads in the valley between the cylinder heads. Also, they should not be tightened carelessly, as they are only fragile little pins whose only function is to secure & position the camshaft bearings.

We bored the cylinders in each block although Nardi recommends that the liners be removed & bored separately. When replacing the cylinders, only two rubber sealing rings should be used on the lower end of the liners, the central groove of the three grooves that will be found on each liner being unused.

Nardi recommend a piston clearance of 0.05 to 0.06 mm, crankshaft & rod clearance of 0.025 to 0.030 mm & crankshaft endplay of 0.05 to 0.08 mm. Nardi write: “The clearance of the rear end of the crankshaft must be 0.12 mm on the diameter”.

Flywheel & Balancing

I had the flywheel lightened a little, but whatever increase in acceleration it gives may not be worth the slight extra roughness at idle. It may make things easier on the clutch because of reduced rotating momentum if the driver indulges in fast, brutal gear changes.

It is a very good idea to dynamically balance crankshaft, flywheel, rods, pins & pistons if the weight of any of the components has changed. The subject of balance is quite complex especially with the Aurelia V^ &its supposed “inherent rocking couple”. I have never had a good explanation & to indicate the confusion one local authority claims that pistons 20 grams heavier than the originals without subsequent rebalancing of the entire crankshaft assembly will result in vibration; another insists that as long as the pistons & rods are matched as to weight there cannot be any imbalance if the crank was originally in balance; a third says the question is academic because it is impossible to achieve perfect balance in a V6!

Intake Manifold & Carburetion

I doubt if the standard GT air cleaner does much as a filter& chassis dynamometer tests have shown that it is definitely restrictive. However, removal of the cleaner or of the wire mesh filter inside it will tend to make the fuel mixture lean, which will require a size or two smaller on the air correction jet or greater size of the main jet, or a combination of both.

Several different multiple carburettor systems have been developed for the 2 litre & 2.5 litre engines. Incidentally, intake manifolds & most other parts are not inter-changeable between these two engines, or amongst the other smaller Aurelia engines. Of course, the Flaminia is a completely new engine.

The Lancia Works at one time raced 2 litre cars with four single throat carburettors & Nardi has produced for the 2 litre both a twin dual downdraught conversion & a weird but ingenious set-up for 6 Dellorto motorcycle carburettors. The latter gave impressive top-end performance, but most owners complained of poor operation below 3000 rpm. (This is confirmed by the difficulties encountered recently by Tim Burrett who worked on a car in the UK with this set-up).

“2 litre B20 engine with 6 Dellorto Carburettors. A Nardi conversion giving 97 BHP” (LMCJ Winter 1970 p.14

Nardi Manifolds

The most successful conversion for the 2.5 litre is the Nardi manifold with two dual downdraught Weber carburettors, although Solex carburettors have been used. Various throttle linkage layouts have been used with this manifold. Those few roadsters & convertibles, which were imported into the USA with this manifold as original equipment, had a U-shaped bracket joining the throttle butterfly arms on each carb. This was not satisfactory & many were changed by removing the bracket & joining the front end of one of the rear Weber’s throttle shafts with the back end of the front Weber’s corresponding throttle shaft.

The 40 DC Weber carb.has separate throttle butterflies for each Venturi, whose shafts lie parallel with the engine crankshaft. They joined in each carb. by a pair of geared sectors.

Joining of the shafts between carburettors was done with a length of steel tubing. This makes a wonderfully simple linkage, but I don’t know how good it is in continuous use.

My dual manifold came from a Nardi with a rather complex linkage in which a shaft is held alongside the two carburettors in ball bearings. Arms are clamped to this shaft, two of which are connected to the throttles of each carb. by ball & socket links. A third arm is similarly joined to the original foot throttle linkage which is unchanged except for a special bracket supplied by Nardi which moves that part of it which is bolted to the engine back a short distance so as to make room for the extra carburettor. A fourth arm on the shaft is connected to a return spring. This type of linkage appears to work well although I found it required reinforcement to the mounting of the ball bearing journals, which as supplied by Nardi is not rigid enough.

Air Box

A very nice air collector box is provided with the dual manifold, although the only air filtration is by a piece of wire gauze. I have connected this box with a piece of heater air ducting to a paper element air cleaner, & so far it works well (see photos on pages above).

Jet Sizes etc.

Nardi recommend the following jet sizes when using 40 DCZ5 or 40 DCL5 carburettors with their manifold: 25 mm Venturis, 4.5 mm auxiliary Venturis, 125 main jets, 210 air compensation jet, 45 pump jet, 50 slow running jets, 175 float valve, accelerator pump exhaust tube closed & weak pump spring. One might of course make changes to this for each engine & locality.

Ignition

Undoubtedly some change to the ignition advance curve may be required & with milled cylinder heads the spark plugs may need to be one range colder than normal. Lodge CLNH plugs are satisfactory for standard engines & Lodge HLN for modified units.

New Paragraph