Routine Servicing of Engine, Gaskets & Seals

This is described in detail in the owner’s instruction book for the various models. Specifications and settings are set out in the first chapter of the Workshop Manual 'General Data & Specifications' above and in the subsequent sections. The maintenance summary for the engine is as follows:

| Before using the car | Check oil level in sump | All models |

|---|---|---|

| Check water level in radiator, top up avoiding hard water | All models | |

| When driving | Check oil pressure gauge | All models |

| Make sure radiator shutters work | All models | |

| After first 600 miles | Change engine oil | All models |

| Remove and clean oil filter | All models | |

| Remove and clean petrol filters | All models | |

| Every 2000 miles/3000 kms. | Change engine oil | All models |

| Tighten distributor greaser 2 turns, fill greaser as required | All models | |

| Grease water pump spindle | All models | |

| Check clearances between valve tappets and rockers | All models | |

| Check cylinder compressions | All models | |

| Check tension of fan belt & adjust as required | All models | |

| Remove and clean petrol filters | All models | |

| Remove and clean engine air filter, lubricate by dipping in engine oil. | All models | |

| Remove, clean & check points gap of spark plugs | All models | |

| Remove and clean oil filter | B10, B21, B20 1991 cc | |

| Every month | Change radiator water using soft water | B10, B21, B20 1991 cc |

| Every 4000 miles/6000 kms. | Renew engine oil filtering element, checking that seal is good after starting engine | B12, B20 2451 cc, all B24 |

| Change radiator water using soft water | B12, B20 2451 cc, all B24 |

Replacing Worn Fluid Hoses

- The original fuel hoses, the engine block to drain tap water hose, and the flexible length in the line to the oil pressure gauge, were all made of laminated yellow fabric, reinforced with spiralled wire. If they still exist on the car, they are commonly in a dangerously brittle condition.

- They may be removed from their original metal end fittings by cutting through the swaged aluminium end sleeves. Try cutting on a 45 º spiral with a hack saw, but take care not to cut too deeply, or the metal fitting inside may be marked.

- The old hose may then be pulled off the end fittings. Try 1/4 inch or 6 mm bore hose for the oil line, 5/16 inch or 8 mm for the fuel pipes, and 3/8 inch or 10 mm for the block drain.

- Use something with reinforced walls for the oil line. Cold pressure would be around 120 psi or 8 atmospheres. Do not risk ordinary unreinforced rubber or plastic, and make sure the hose clips fit properly. These replacements may not be as original, but will avoid a worn out part bursting and dumping the oil or water on to the road.

By Tim Burrett, LMC/NS Jan. 1988 No. 237

- Stainless steel clad flexible hoses are a sensible, if not original, replacement especially for pressure hoses. Goodridge (UK) Ltd is a supplier of such parts.

- Replicas of the original hoses are available, and could be made up with the original unions but as mentioned above, better materials are now available and these should be preferred.

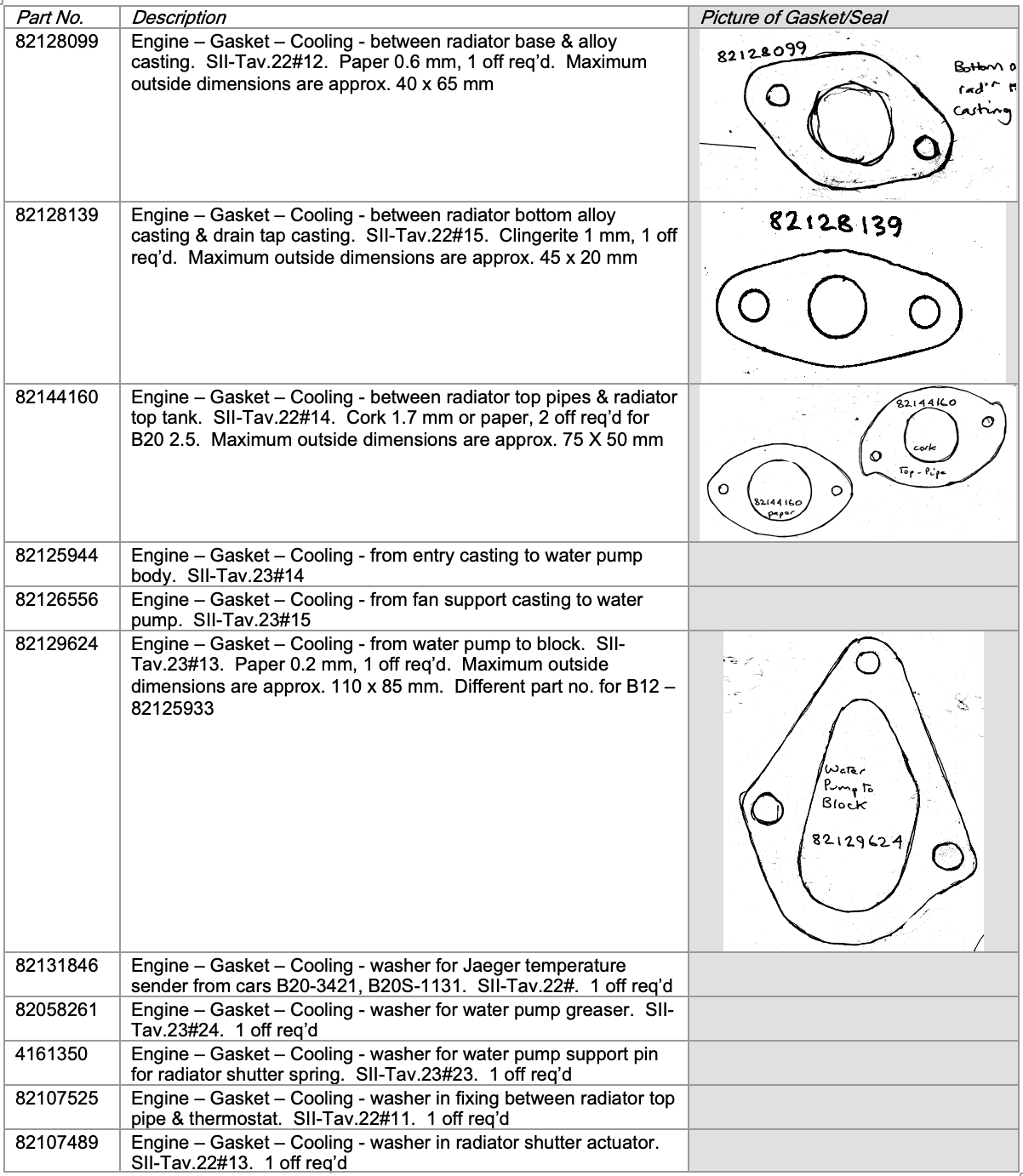

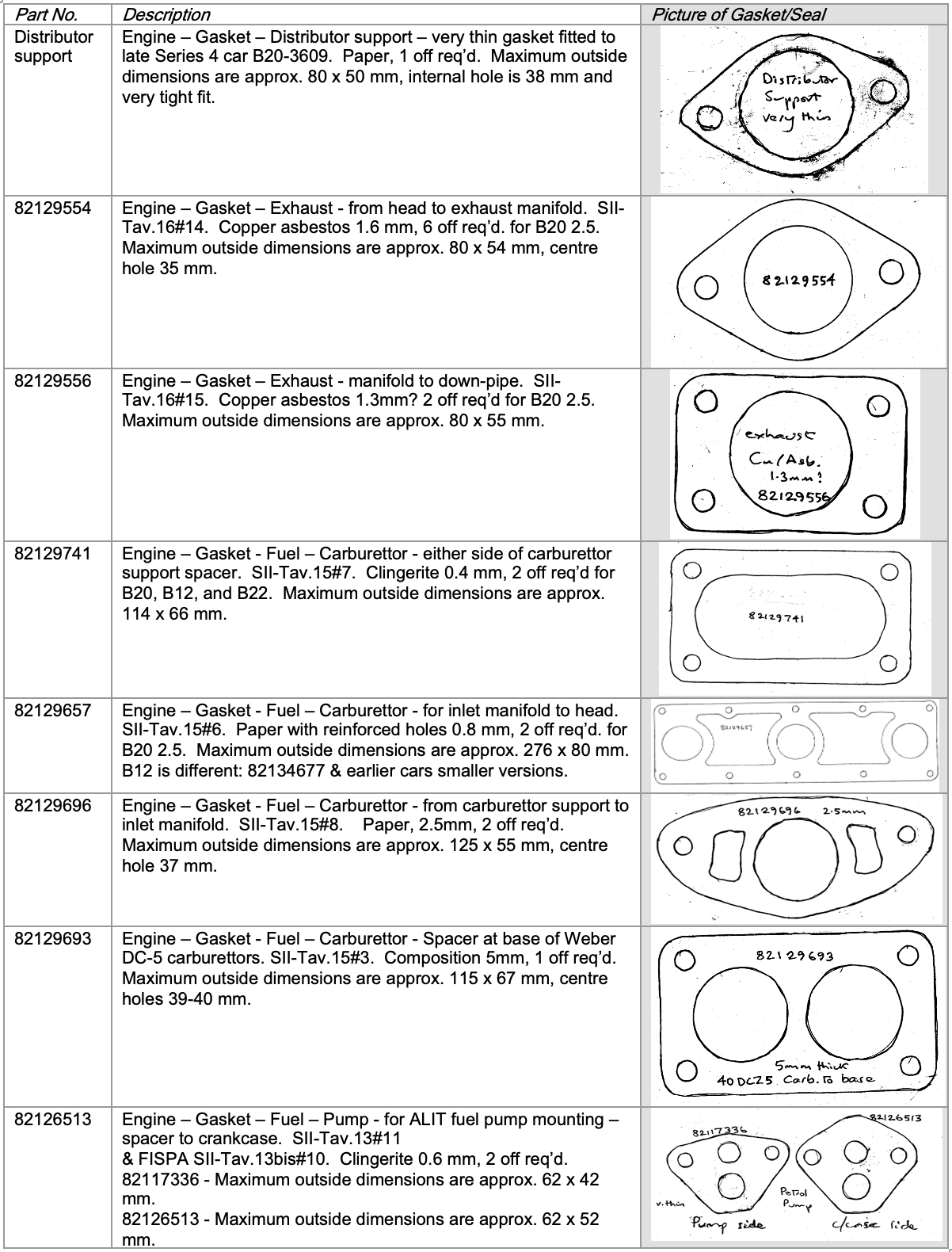

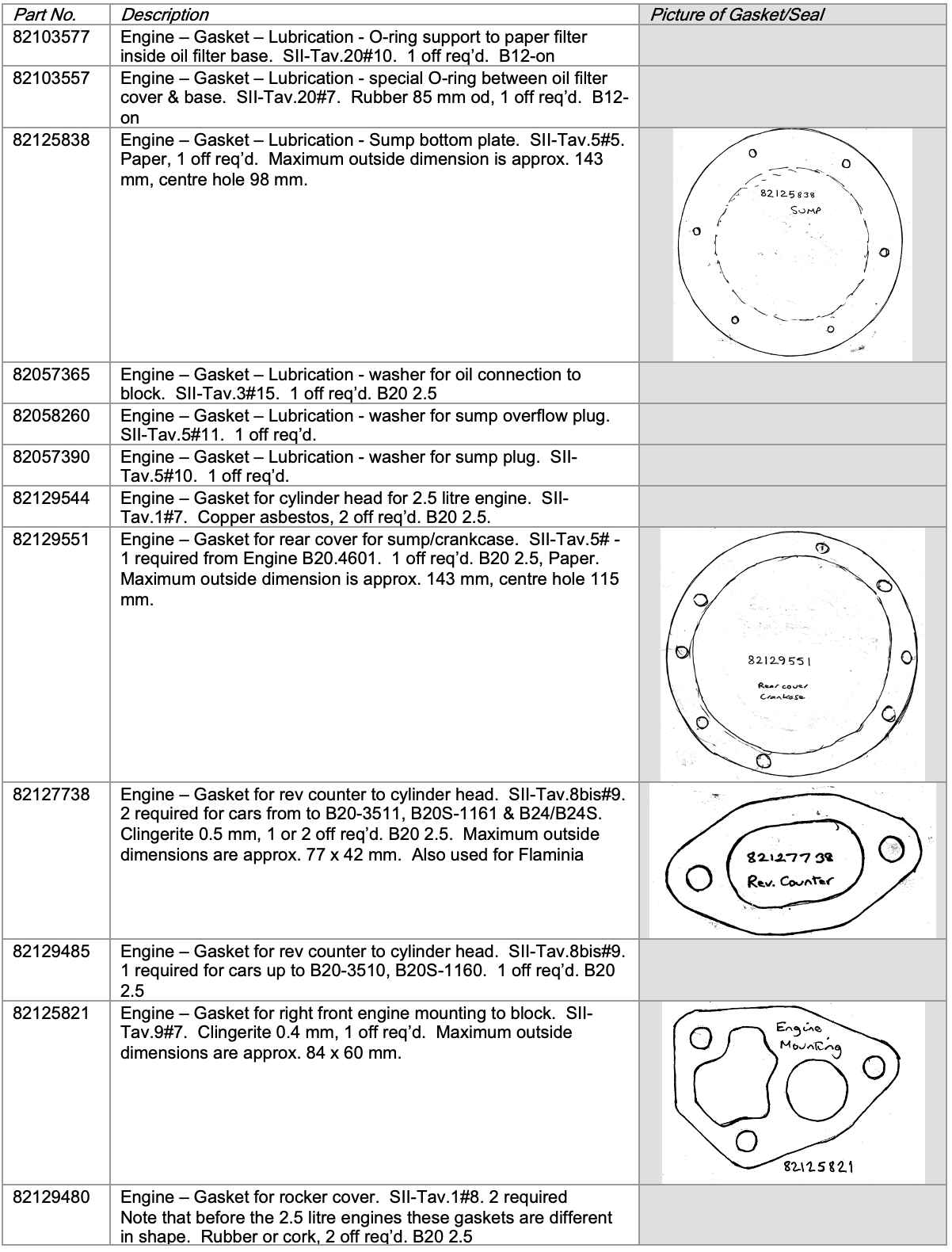

Gaskets & Seals for the Engine

B12 Engine Right-hand side [Ref. 15]

B12 Engine Left-hand side [Ref. 15]

B20 6thSeries Engine, but B20 4th& 5thSeries very similar [Ref. 15]