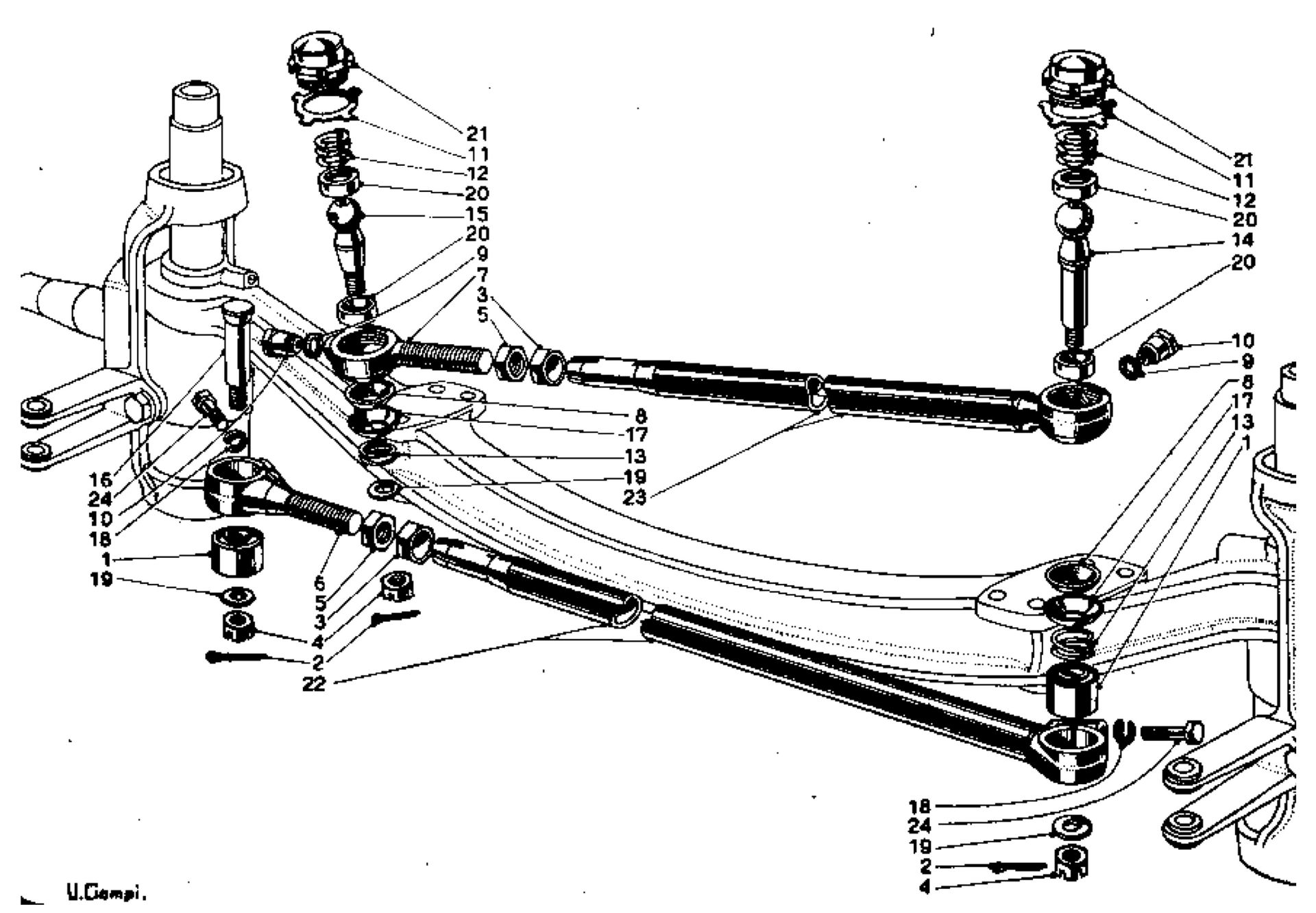

Steering Arm, Track Rod & Toe-in

The steering arm and track rod assembly was almost the same throughout Aurelia production. SII-Tav.48 below shows the details. Refer also to Tav.50 in Front Suspension General Description.

Notes on Part Numbers from SII-Tav.48.

- #1 are Silent bloc bushes, RIV No.U541/Autoparti SBL059/Lancia 2049629. Dimensions are: 30mm od, centre sleeve is 17mm od, 12mm id, & 27.8mm long

- Locking nuts #3 and #5 also varied. #3 may be 6-sided or with 2 flat faces – it is a cone-shaped collar, not a nut.

- Nuts #4 are 17mm.

- Nuts #5 are 22mm.

- The greasers #10 were of the later ball-type on B20/B24 5th and 6th series. They should be refilled every 3000 km with Mobilgrease 2/Esso chassis grease H or equivalent.

- #20 (Lancia 2127162) are bronze cone-shaped housings for track-rod ball-joints #15. The bronze tends to wear rather than the steel ball. They should be cleaned and repacked with chassis grease. Dimensions of #20 are 26mm od & 8mm deep.

- Some steering arms #22, #23 were not adjustable. When they are, the adjusting end is split and cone-shaped.

- #24 are 10mm with spring washers #18.

Adjustment of Toe-in

Refer to Tav.48 above. Data from AST Sketch 1059 I 18.2.65

Toe-in Data

| Model | Toe-in measured with wheels off the ground, at wheel rims | |

|---|---|---|

| mm | inches | |

| Series I, B12, B20 1st-4th series B24 4th, B24S-1001 to 1181 | 0 to 2 | 0 to 0.079 or 5/64 |

| B20 5th & 6th B24S from 1182 | 4 to 6 | 0.157 to 0.236, or 5/32 to 15/64 |

Procedure

- Remove split-pin #2 from right hand ball joint on track-rod #22.

- Undo nut #4 and drive out #16 upwards to release track-rod from pillar.

- Undo nut #5, knock collar #3 back from cone, loosen lock washer.

- Take opportunity to check Silent blocs #1 and replace as required.

- To adjust toe-in, rotate #6 360 degrees at a time. Note that on late B20 and B24 cars locating pin #16 is eccentric and allows for some adjustment without removing track-rod.

- Clean all parts and grease before reassembly.

- Refit joint and tighten nuts #4 and #5.

- Test toe-in, preferably with an optical alignment system.

- Wear in the Silent blocs #1, ball-joints #15, 20 and steering box will all affect toe-in and steering inaccuracy. At worst, the front axle could be out of alignment.