Engine Lubrication

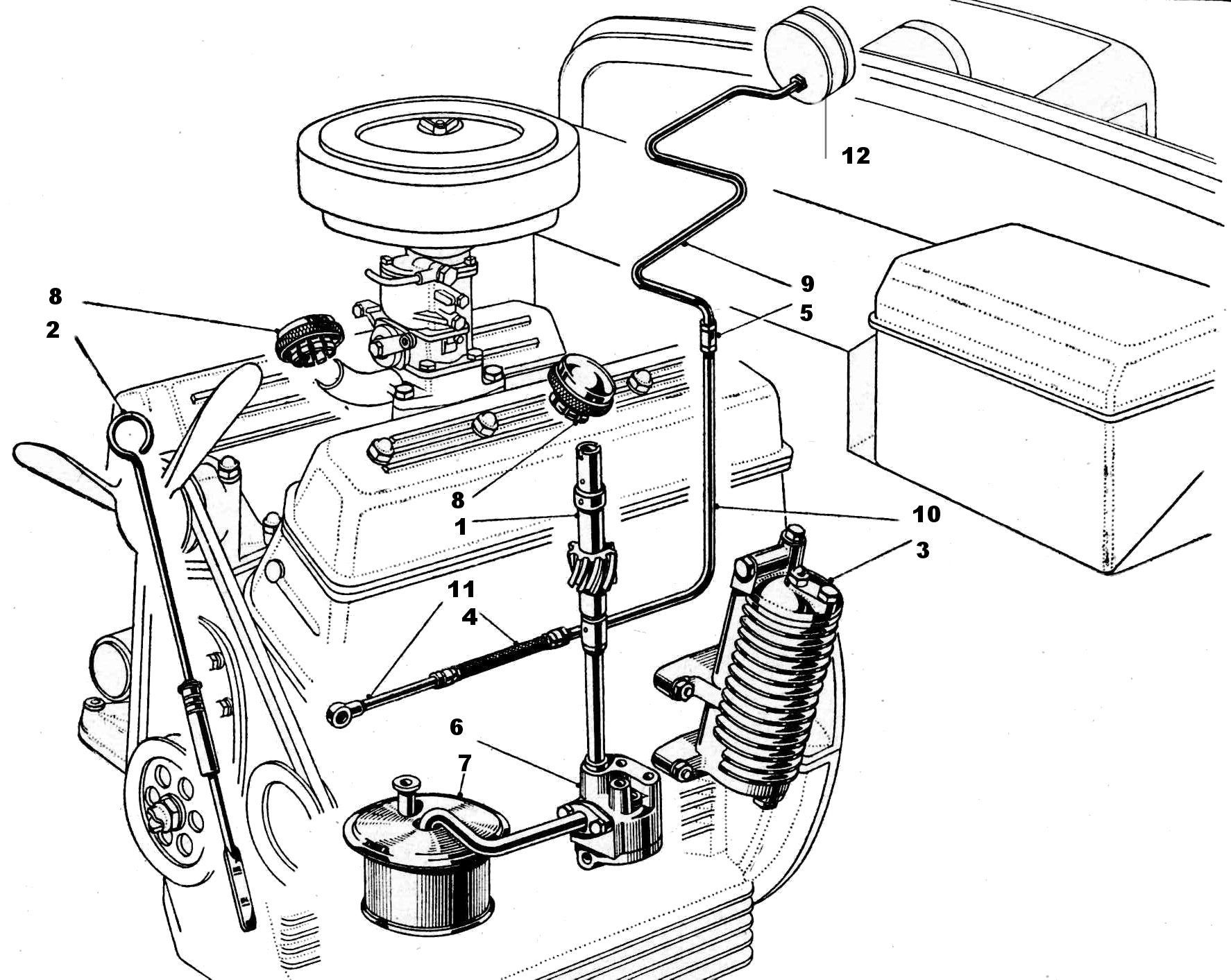

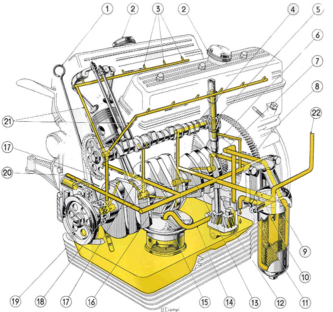

Scheme of the Lubrication System - Series I Cars

Tav. 9 Engine Mountings

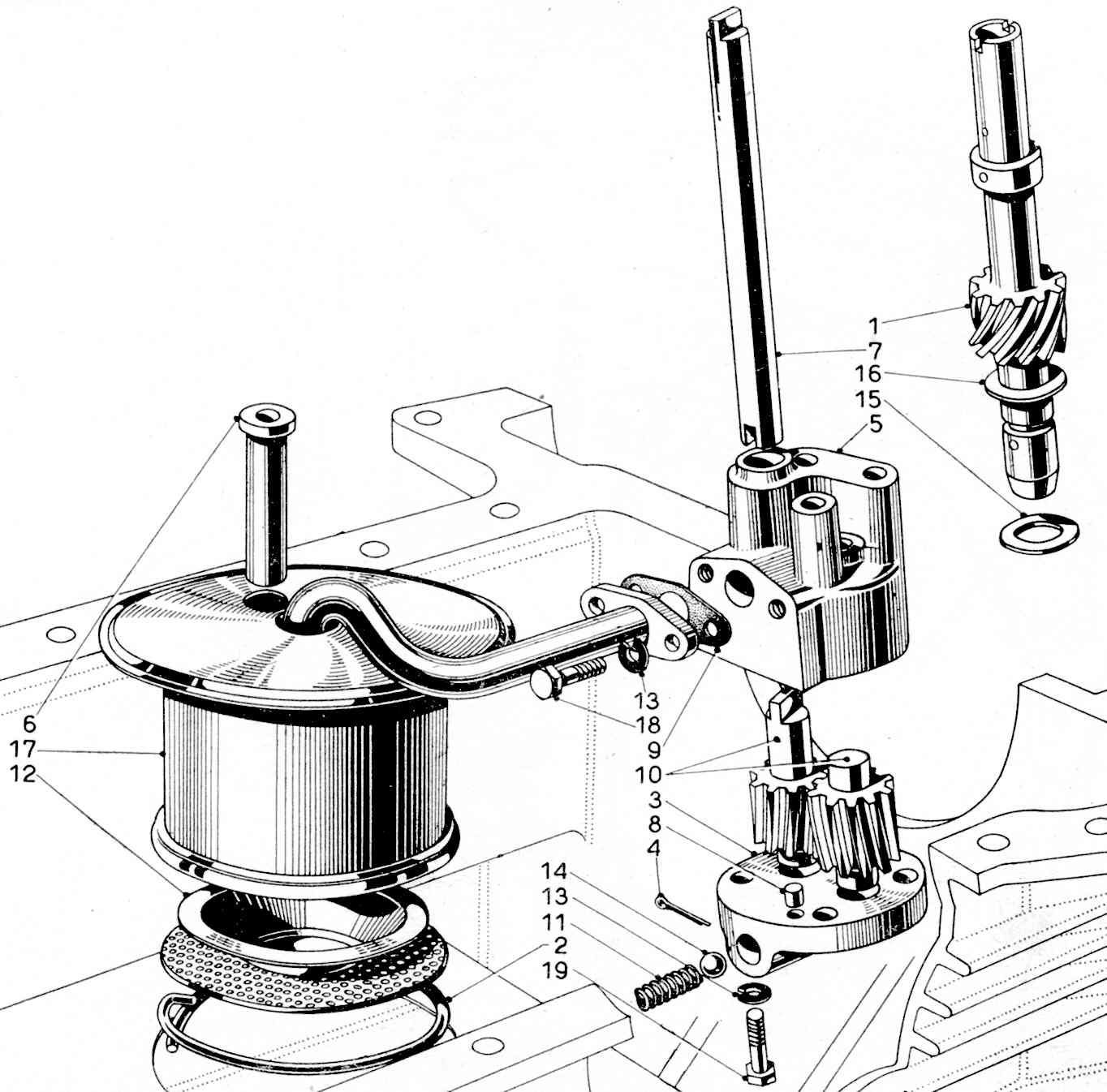

Series I Cars (Tav. 17)

| Ref. in Tav. 17 | Description of Series I System | No. Used |

|---|---|---|

| 1 | Drive for oil pump & distributor | 1 |

| 2 | Dip-stick – 2 types, later type from B20-1797 (incl. B20-1795) | 1 |

| 3 | Oil filter, complete – gauze insert requiring cleaning | 1 |

| 4 | Flexible pipe supplying oil pressure gauge | 1 |

| 5 | Joint in oil supply to oil pressure gauge | 1 |

| 6 | Oil pump complete | 1 |

| 7 | Sump oil scavenger – 2 types, later type from B20-1797 (incl. B20-1795) | 1 |

| 8 | Oil filler caps in rocker covers | 2 |

| 9, 10 & 11 | Rigid oil pipes to oil pressure gauge – vary for LHD & RHD & in & between models | 1 of each |

| 12 | Oil pressure gauge | 1 |

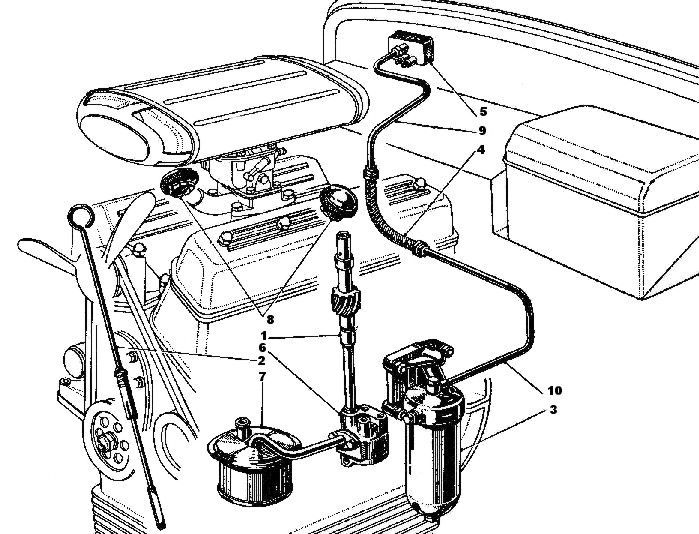

Scheme of the Lubrication System - Series II Cars

Series II Cars (Tav. 18)

| Ref. in Tav. 18 | Description of Series II System | No. Used |

|---|---|---|

| 1 | Drive for oil pump & distributor – same as Series I. Changes from B20-3511/B20S-1161 & for B24 | 1 |

| 2 | Dip-stick | 1 |

| 3 | Oil filter, complete – Carello FHM-LAN disposable paper filter inside can. This item 11007877 is used on all Series II cars, B12, B24 and B24 | 1 |

| 4 | Flexible pipe supplying oil pressure gauge | 1 |

| 5 | Oil pressure gauge – There is an error in the description of this part which is made clear in Tav. 69 | 1 |

| 6 | Oil pump – changed from engine B20.4488 & also from engine B24.1202 | 1 |

| 7 | Sump oil scavenger – similar to Series I | 1 |

| 8 | Oil filler caps in rocker covers | 2 |

| 9 & 10 | Rigid oil pipes to oil pressure gauge – vary for LHD &RHD & in & between models. For the B12 there are 5 versions of #9. | 1 & 1 |

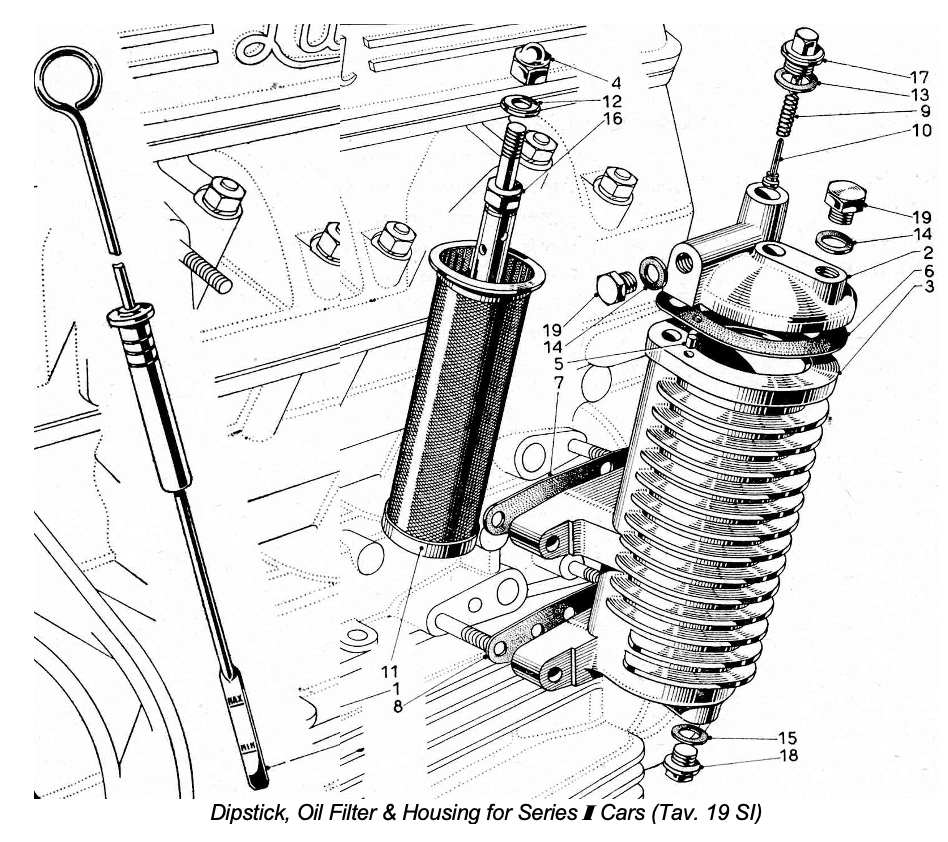

Oil Filters

Oil Filters

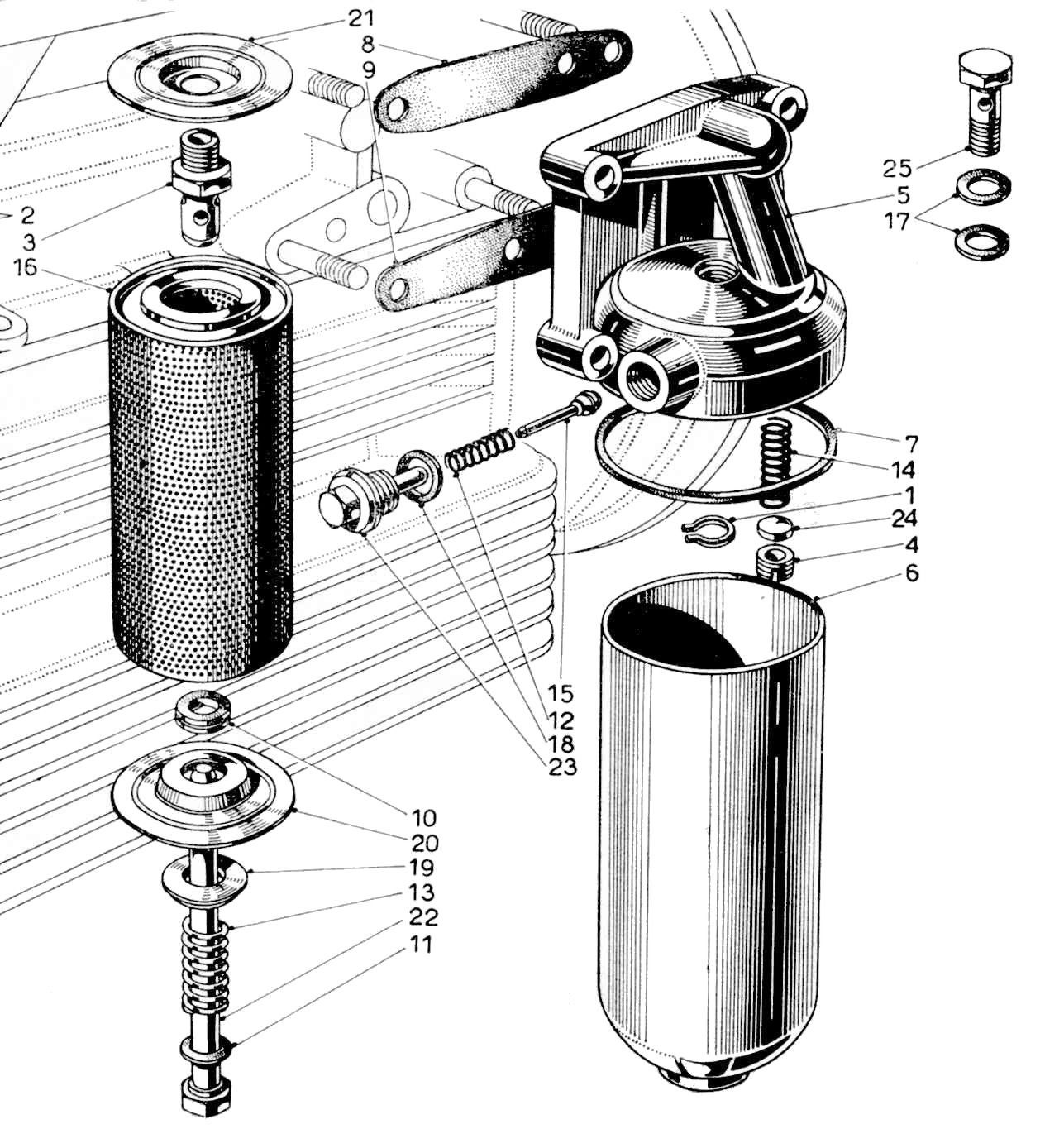

Series II Oil Filter (Tav. 20)

| Ref. in Tav. 20 Series II | Ref. in Tav.19 Series I | Description of Oil Filter System | No. Used |

|---|---|---|---|

| 7 | Rubber seal between filter holder & upper body. Usually supplied with filter. Take special care to fit this rectangular section ‘O’-ring properly into its seating as failure of this will result in oil leaks. | 1 | |

| 16 | Paper oil filter: there are many fittings from various suppliers. Some of the following may be obsolete: Fram CH801PL, CH825PL, CH811PL, CH993PL AC 34A or B (2.4, 3.4, 3.8, 240, 420 Jaguars) Wix 902BP, Purolator MF 75A/4, GUD GP172, Thor F801, R200IP, AFL129, Tecalemit FG2344, FP3313, FP3300, FG2412, FG2303. Filters should be changed every 6000 km/4000 miles | 1 | |

| 12, 15, 18, 23 | 9, 10, 13, 17 | Low pressure relief valve (the other relief valve is in the oil pump - see below). All parts are the same through Series II and the cap (#23, #17) and washer are same as Series I models. There are 3 types of spring: One for the B10/Series I but a B20 part for the 3rd Series B20 and B22. The complete oil filter B12 part 11007878 applies to all Series IIcars. | 1 of each |

Oils to be Used

The recommended oil was Mobiloil Special or Esso Extra 10W, 20W or 30W. Any good quality oil is fine, e.g. Castrol GTX 20W/50. All engines have oil capacity of 4.5 to 5.0 litres, which should be changed every 3000 km.

- The following is extracted from an article by Martin Cliffe ‘Oils for Classics’ in Viva Lancia!magazine, August 1993, p17 & was written following contact with Penrite Oil Co. Ltd.

- I have been through all the Lancia I could lay my hands on & with Penrite’s help have translated these into modern equivalents. It is unquestionably true that older engines, designed with large clearances when new& generally exhibiting some wear, perform better on thicker oils. A modern multigrade of say 10W/40 can result in leakage via the valve guides & oils seals, as well as past the piston rings. Using a straight oil is not a good idea, as it creates so much friction or viscous drag that starting can be difficult, so a ‘thick’ multigrade is the answer as it will be thin enough in a cold engine to allow a high cranking speed, & rapid circulation.

- The Penrite approach has been to go back to the original oil thickness specification of the manufacturer. They produce a range of multigrades that meet these requirements, & which both match the original viscosity criteria & use the best additives available from today’s research. This has led to the introduction of the HPR collection, which is a range of full-bodied detergent oils in a multigrade format.

- Three products are available, HPR 30, 40 & 50 (whose grades are 20W/60, 25W/60 & 40/70 & which respectively replace 20/50 & straight SAE30, SAE40 & SAE50). Straightaway the grade structure advantages are apparent: what many owners find is that oil pressure increases & engine temperature decreases.

- Penrite’s recommendation is that HPR 30 is correct for newly rebuilt engines, with HPR 40 being better suited to hot running engines or high mileage engines, & competition use.

- All these oils meet the API specification SG. This refers to the American Petroleum Institute tests for the performance of oils for spark ignition engines (hence the S), & G is currently the highest level possible. Not all high street oils come close, & it is still possible to find SE & SF oils. Read the label, most brands state the grade clearly, but not all.

- For older engines that have not been rebuilt (including thorough internal cleaning) there will be almost certainly be some heavy sludge deposits & use of a detergent oil can be a mistake, as the accumulated deposits can dissolve & start to circulate with the oil. The best choice for such engines is a non-detergent multigrade (almost impossible to buy on a garage forecourt these days), but fortunately Penrite can provide it in three viscosities. These are known as the Shelsley range, available as ‘30’ (20W/50), ‘40’ (25W/60) & ‘50’ (40/70). These oils contain a full range of additives with the exception of the detergents & dispersants, & so provide a high degree of protection to wearing parts.

Oil Pump

Series I & II Oil Pump (Tav. 18 SI & Tav. 19 SII)

The pumps are very similar & many parts identical for all models

- Oil level dipstick

- Oil filling plug

- Oil ducts to rocker arm supports

- Oil ducts to rear camshaft bearing

- Driven gear for oil pump control

- Oil duct for lubrication of oil pump shaft

- Oil duct to rear main bearing

- Piping from pump to oil strainer

- Filtering element

- Piping from strainer to manifold

- Pressure regulating valve delivering under the pump

- Oil pump

- Oil duct to crankshaft & camshaft bearings

- Oil suction pipe

- Suction filter

- Oil delivery manifold

- Oil ducts to connecting rod bearings

- Oil duct to front main bearing

- Oil sump

- Oil duct to front bearings of crankshaft, camshaft & chain stretcher

- Oil ducts to valve control rockers

- Delivery pipe to oil pressure gauge

Engine Lubrication diagram from B20 6th series instruction book 001188 (1958)